An intermittent no-crank condition is one of the most misleading electrical faults in modern vehicles.

The engine starts normally for days, then suddenly refuses to crank. Later, without repair, it starts again.

This behavior leads to misdiagnosis, unnecessary parts replacement, and unresolved customer complaints.

The problem is not randomness. It is a conditional failure.

This article explains intermittent no-crank diagnosis from a technician’s perspective.

You will learn why these faults disappear during testing, what conditions trigger them, and how to isolate the failure logically instead of guessing.

Contents

What “Intermittent” Really Means in Electrical Diagnosis

Intermittent does not mean unpredictable. It means the circuit fails only when specific conditions are present.

Those conditions typically include:

- Heat

- Vibration

- Load

- Time

- Electrical resistance changes

When those conditions are removed, the circuit temporarily behaves normally.

Why Intermittent No-Crank Faults Are Hard to Catch

Most testing is performed when the vehicle is:

- Cold

- Parked

- Not under vibration

- Not under electrical load

In other words, the fault-triggering condition is absent.

As a result:

- Voltage appears normal

- Continuity tests pass

- Scan tools show no faults

The circuit only fails in real operating conditions.

The Three Systems That Cause Intermittent No-Crank

Every intermittent no-crank can be traced to one of three systems:

- Power delivery

- Ground integrity

- Control signal authorization

If all three are stable under load, cranking will occur.

Heat-Related Intermittent No-Crank Failures

Heat changes electrical behavior.

Common heat-related failures include:

- Starter relay contacts expanding

- Ignition switch internal resistance increasing

- Solenoid windings drawing excessive current

- Marginal grounds losing conductivity

These faults often appear:

- After a hot soak

- In traffic

- After extended driving

Once the vehicle cools, normal operation returns.

Vibration-Induced Circuit Failures

Vibration exposes weak electrical connections.

Typical causes include:

- Loose ground bolts

- Cracked relay solder joints

- Worn ignition switch contacts

- Stretched or corroded terminals

A stationary vehicle may test perfectly. Movement recreates the failure.

Why Voltage Drop Matters More Than Continuity

Continuity tests only confirm a path exists. They do not confirm the path can carry current under load.

Intermittent no-crank faults are almost always voltage drop issues.

Examples:

- A ground strap with corrosion

- A relay contact with pitting

- A terminal with surface oxidation

Under load, resistance increases and voltage collapses.

Starter Control Signal in Intermittent Conditions

The starter control signal may appear intermittently due to:

- Failing starter relays

- Heat-sensitive ignition switches

- Control module authorization delays

- Security system logic interruptions

A momentary signal loss prevents cranking, even if power and ground are present.

👉 See: Starter Control Signal Diagnosis

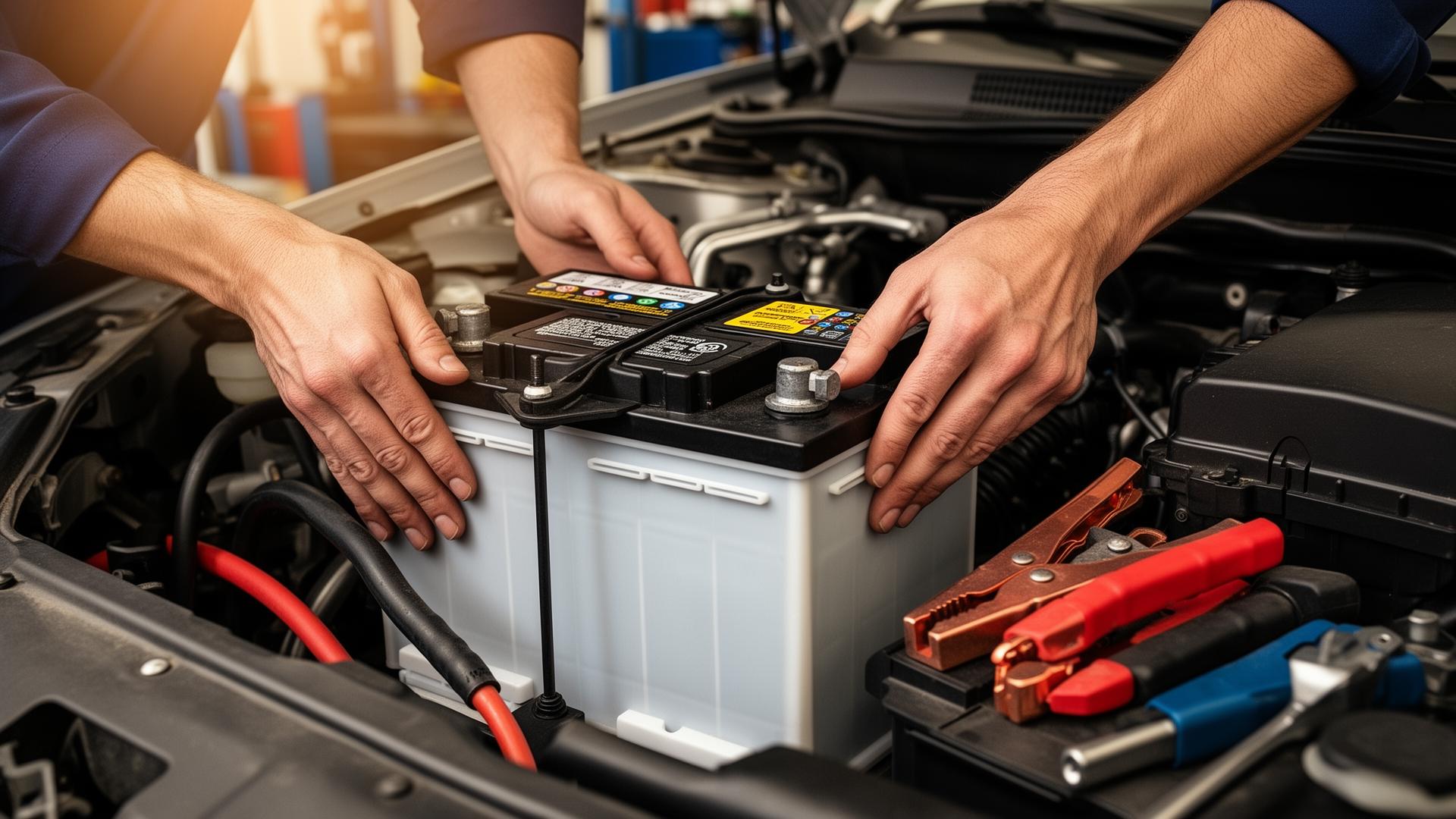

Ground Integrity Under Real Conditions

Grounds often pass static testing but fail dynamically.

Heat, vibration, and load exposure:

- Poor metal-to-metal contact

- Paint contamination

- Corrosion under fasteners

An unstable ground can interrupt starter operation without visible damage.

👉 See: Engine Ground Strap Symptoms

How to Diagnose Intermittent No-Crank Correctly

The goal is not to test harder. It is to test smarter.

Key strategies:

- Test during the failure

- Load the circuit while testing

- Monitor voltage drop instead of continuity

- Use heat or vibration to recreate conditions

If the fault cannot be reproduced, it cannot be confirmed.

Diagnostic Decision Logic

Use this logic when the failure occurs:

- Battery voltage stable but no crank → Check control signal

- Control signal present but no crank → Check power and ground under load

- Failure only when hot → Suspect heat-sensitive components

- Failure only when moving → Suspect vibration-sensitive connections

Follow the logic, not assumptions.

Common Misdiagnoses

Intermittent no-crank conditions are often misdiagnosed as:

- Bad battery

- Failed starter

- Faulty ECU

These components are replaced because the real fault is hidden during testing.

Where This Fits in No-Start Diagnosis

Intermittent no-crank diagnosis sits at the intersection of:

- Electrical logic

- Real-world operating conditions

- Accurate load testing

It connects power, ground, and control failures into a single diagnostic framework.

👉 See: Electrical No-Start Diagnosis

Conclusion

Intermittent no-crank faults are not mysterious. They are conditional.

When the diagnosis focuses on static testing, these faults remain hidden. When testing is performed under real conditions, the failure reveals itself.

Electrical systems follow rules. When heat, vibration, or load violates those rules, the engine does not crank.

Understanding those conditions transforms intermittent no-crank diagnosis from guesswork into controlled, repeatable testing.

Leave a Reply